We often see in machinery and equipment that some bolt connections use washers, some bolt connections do not use washers, some bolt connections use flat washers, and some use spring washers. What do we need when designing? Don't use washers? So entangled, have you ever entangled the same. If so, today's article is for you.

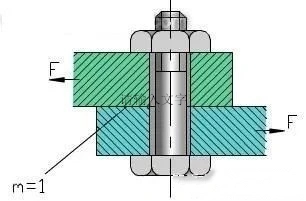

Bolt connection-no washers

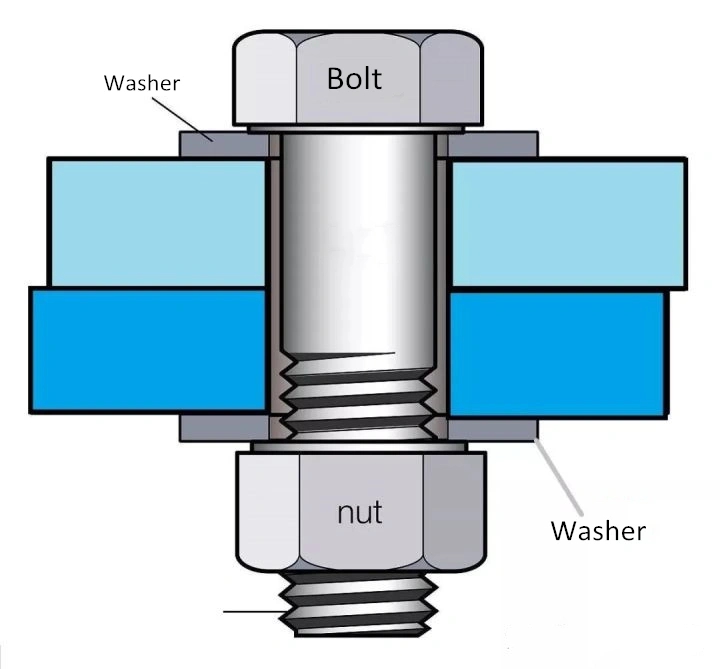

Bolt connection-with flat washers

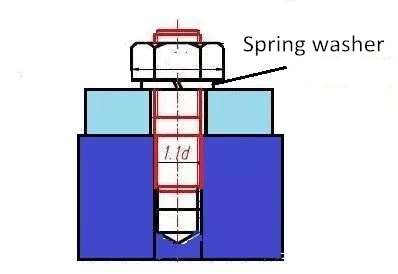

Stud connection-spring washer anti-loosening

What does the gasket do?Flat Washers

1. When the bolts need to be disassembled frequently, in order to protect the surface of the connected part from being scratched, it is generally necessary to place a flat washer at the position of the nut or bolt head, so as to prevent the surface of the connected part from being scratched.

2. In some joints where the friction coefficient is required to be more precise, such as high-strength prestressed bolts, flat washers are required at the nut end. In this case, the bolts, nuts, and washers are all provided by the same manufacturer. The bolt manufacturer needs to correct Nuts and washers are treated accordingly to ensure that the coefficient of friction between the nuts and washers remains consistent.

3. When the bolt strength is relatively high and the allowable compressive stress of the connected part is relatively low, in order to reduce the compressive stress of the pressure-bearing surface of the connected part, it is generally necessary to add a flat washer.

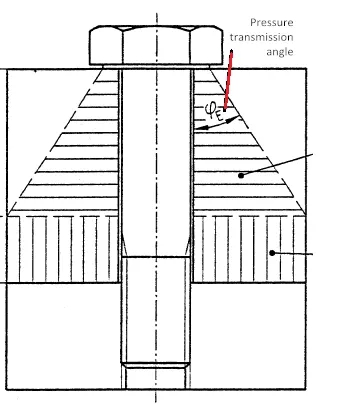

4. In a bolt connection, the pressure transmission of the bearing surface of the bolt head or nut is gradually enlarged in a trumpet shape. The larger the bearing surface, the smaller the compressive stress. Therefore, the addition of a flat washer can reduce the compressive stress of the contact surface of the connected part. Ensure that the bolt connection is effective.

1. In some occasions, in order to ensure the one-to-one correspondence between the bolt holes between the two connectors, we need to increase the diameter of the hole to compensate for the position deviation of the hole. When the bolt hole exceeds the standard requirement, we need to add a flat washer. 2. Sometimes for the convenience of installation and adjustment, the bolt holes are made into long holes, so that the installation position of the workpiece can be adjusted within a certain range. When long holes are used, thick flat washers must be used, or even special washers or more washer.

Spring washer

1. The main purpose of spring washers is to relax. They are generally used in occasions where the bolt pre-tightening force is not high and the dynamic load is small.

2. When the clamping length of the bolt is relatively short, the bolt stress relaxation is more obvious, and the spring washer can compensate for the stress relaxation.

3. Experiments have shown that under dynamic load conditions, high-strength bolted spring washers have almost no anti-loosening effect, and will cause rapid attenuation of bolt clamping force. Therefore, spring washers are rarely used in high-strength bolt connections abroad. .

Under what circumstances are bolted connections need washers, we already know more clearly, then under what circumstances can washers be unnecessary?

1. Shear stress bolt connections generally do not need washers. First of all, the bolts do not need too much pre-tightening force and do not bear axial force during work. In this case, the bolt holes are generally small, and the bearing surface of the nut or bolt head Generally, they are relatively large, and there is no need to reduce the compressive stress, and the connected parts can bear it.