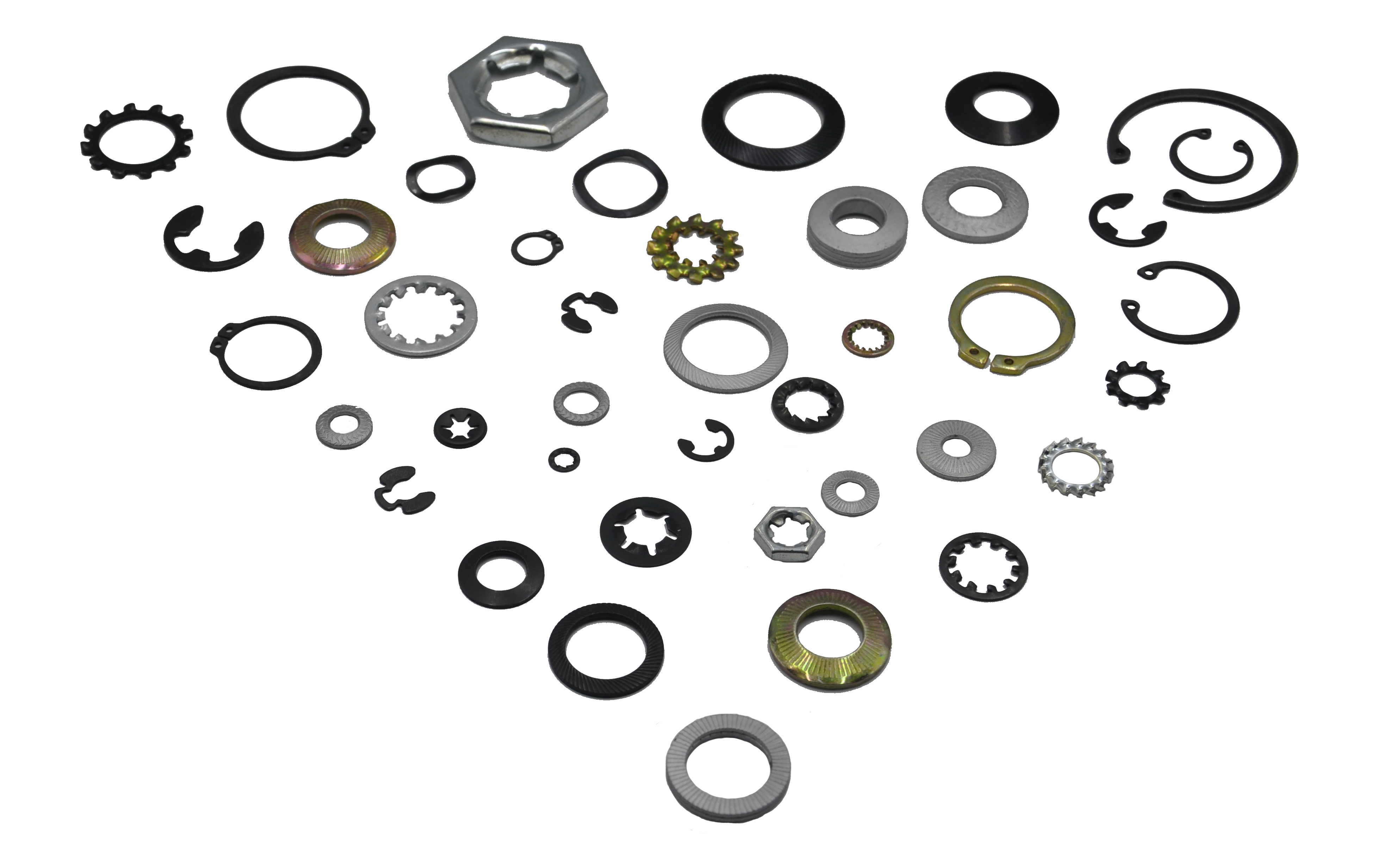

Washers mainly include flat washers, spring washers, lock washers, sealing washers and special-shaped washers for other purposes.

1. Flat plain washer

Flat pad is a kind of thin part for the purpose of reducing friction, protecting the connecting surface or dispersing the pressure. Flat washers are common with flat metal rings. Their application is mainly for the purpose of reducing friction, isolating and dispersing pressure. What are the common flat washers? Most fasteners involve flat washers, such as ordinary flat washer DIN 125A / ISO 7089 / GB 97.1, chamfered flat washer DIN 125b / ISO 7090 / GB 97.2, class C flat washer din126 / ISO 7091 / GB 95, large outer diameter washer DIN 9021 / ISO 7093 / GB 96.1.

There are differences in the hardness performance of flat washers of different standards (the following are mainly flat washers and large outer diameter washers). The performance of washers is slightly different in terms of hardness, which can be selected according to the actual working conditions, and the specific performance shall be subject to the relevant product standards.

2. Spring washer

After the connecting pair is tightened, the spring washer relies on the reaction force released by itself to enhance the axial tension between the connecting pairs, so as to increase the friction and prevent looseness. Common spring washers mainly include heavy spring washer DIN 127a / GB 7244, standard spring washer DIN 127b / GB 93, saddle spring washer DIN 128A / GB 7245, corrugated spring washer DIN 137A / GB 860 and DIN 137b / GB 955, conical elastic washer din6796 / ISO 10670 and other product standards.

3.Lock washer

As the name suggests, the lock washer is a washer that plays a locking role in the connecting pair. This paper mainly introduces the tab washer based on mechanical fixation and the washer to increase the friction to achieve the locking function.

Tab washer: relying on the mechanically fixed tab washer, it can prevent the relative movement between the thread, the connected part and the threaded connection pair, so as to prevent loosening. There are various forms of tab washers, mainly including single lug tab washer, double lug tab washer, inner tongue tab washer, outer tongue tab washer, etc. Among them, take the application of single lug stop washer as an example: after the bolt passes through the single lug stop washer, fold the "long tongue" of the washer close to the edge of the connected part, and then stand up the round ear of the washer, so as to achieve the purpose of stopping.

Lock washer: this kind of lock washer mostly achieves the purpose of locking by increasing friction. There are many common types, such as SK tooth face self-locking washer and double-sided locking washer.

4.Other washers

In addition to the above common washer types, there are more washers for other purposes, such as sealing washer, spherical washer, etc. Sealing washer: sealing washer can be used where there is fluid to prevent leakage. It is often seen in the sealed connection between pipes and between parts of machinery and equipment. According to the material, the sealing washer mainly includes metal sealing washer, non-metallic sealing washer, etc. Metal materials commonly include copper, aluminum, etc. Non metallic materials include rubber, asbestos fiber, etc. Spherical washer: the spherical washer is used together. During installation, the position can be automatically adjusted to make the force uniform, increase the friction and play a certain role in preventing looseness. It can be seen that there are various types of washers, and each washer is given its own responsibilities and roles.

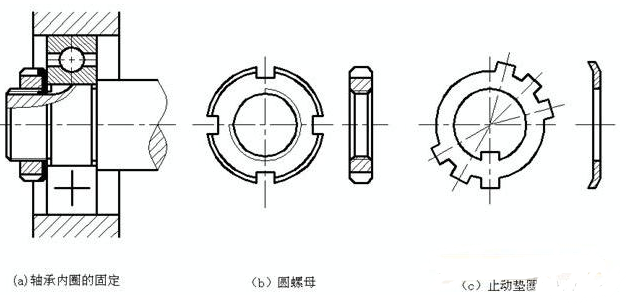

Installation of washer

The washer is used together with the round nut. When in use, the washer is installed on the slotted side of the nut. After fastening, bend the inner and outer stop lugs into the slot. After the round nut is fastened, pull the inner and outer ears into the axial direction respectively and clamp them on the keyway on the shaft and the opening of the round nut respectively, so that the round nut will not loosen due to the rotation of the shaft.

Note: when the round nut is installed with a tab washer, the side to which the internal teeth bend faces the round nut or back to the round nut?

When the round nut is tightened in place, the internal teeth of the tab washer bend towards the round nut. One of the external teeth of the tab washer is bent into the groove of the outer wall of the round nut, and the internal tooth is clamped in the groove on the threaded rod, so that the tab washer does not move relative to the screw rod when the round nut is screwed in.