Why do bolts need to be preloaded?

1. Prevent the connection from loosening and enhance reliability;

2. The joint surface of the connected parts has sufficient tightness;

3. Generate friction on the joint surface to withstand lateral loads;

Anti-loosening purpose of bolted connection

1. In actual work, the external load has vibration, changes, high temperature creep of materials, etc., which will reduce the friction force;

2. The positive pressure in the threaded pair disappears at a certain moment and the friction force is zero, so the threaded connection is loose. If it is repeatedly acted, the threaded connection will loosen and fail. Therefore, it is necessary to prevent loosening, otherwise it will affect the normal work and cause accidents.

Anti-loosening principle of bolted connection

1. Eliminate (or limit) the relative movement between thread pairs;

2. Increase the difficulty of relative movement;

What are the methods of preventing loosening of bolts?

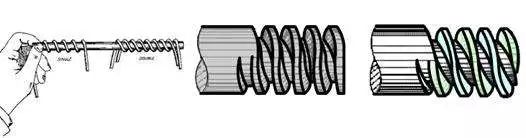

1. Friction and anti-loosening;

2. Mechanical anti-loosening;

3. Permanent anti-loose;

What are the forms of bolt failure?

1. The bolt rod is cut and damaged;

2. The hole wall is crushed and damaged;

3. The plate is pulled off;

4. The end of the plate is cut off;

5. The screw is bent and damaged;

What are the structural and process requirements for high-strength bolts?

1. The high-strength hexagon head bolt connection pair consists of a bolt, a nut and two washers, and the torsional shear type high-strength bolt connection pair consists of a bolt, a nut and a washer;

2. The temperature of the installation environment should not be lower than -10℃;

3. High-strength bolts should be able to freely penetrate the bolt holes during on-site installation, and must not be forced to penetrate;

4. The high-strength bolts need to be replaced if they are over-tightened, and the replaced bolts should be discarded and not reused;

5. The length of high-strength bolts should be calculated on the basis of the exposed 2-3 button wires after the final screwing of the bolt connection pair;

What are the tightening requirements for bolts?

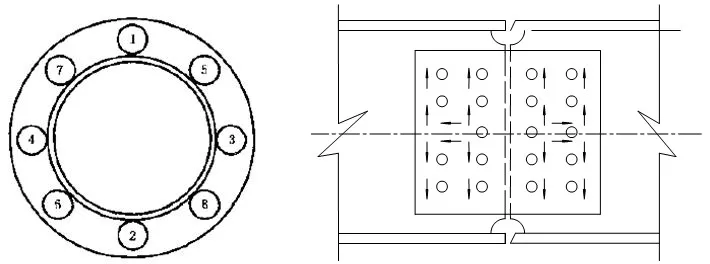

1. Tightening of ordinary bolts: The tightening sequence of bolts should start from the middle and proceed symmetrically to both sides. The tightening construction of the bolts is based on the operator's feel and the shape of the connecting joint. For large joints, double tightening should be used, that is, two tightening methods ensure that each bolt in the joint can be evenly stressed;

2. The initial screwing, re-twisting and final screwing of the high-strength bolt connection pair should be carried out in the order of the parts with higher joint stiffness in the direction of less restraint and the center of the bolt group to the surrounding areas; the connection joints of high-strength bolts and welding should be According to the construction sequence of bolting first and then welding;

What does the thread do?

1. Fastening and connecting functions: suitable for most screw products at this stage;

2. Transmission effect (displacement effect): such as the micrometer used by QC to check the size;

3. Sealing function: such as the connection sealing of pipes;