Double-stack self-locking washer is one of the important anti-loose assembly components that are indispensable in industrial assembly, and also belongs to the fastener with high safety level.

The installation of the double-stack self-locking washer is very simple. It is only necessary to combine the inner helical tooth surfaces of the two washers and place them between the nut and the connecting material. The radial bulge on the outside of the nut will connect with the metal material.

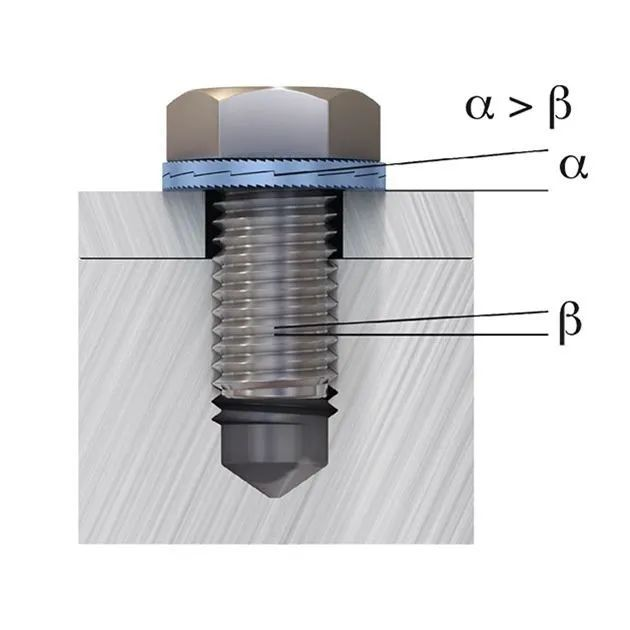

When the nut is tightened, the radial convex surface on the outer side of the double self-locking washer and the contact surface at both ends are in an occlusive state, and the slope angle of the bevel tooth surface on the inner side of the washer is greater than the bolt thread angle.

In order to ensure that the self-locking washer does not follow, the contact surface between the self-locking washer and the bolt and the connected part is a radial fine helical tooth surface, and the hardness setting of the washer after heat treatment with alloy steel or special steel is relatively large, so as to ensure that the helical tooth surface of the lock washer and the contact surface of the bolt and the connected part are in a bite state after stress.

The other side of the washer adopts a wedge angle larger than the bolt rising angle. When the bolt is subject to vibration and the bolt tends to loosen, there is only relative dislocation between the two gaskets. Because of the increase of the wedge angle, the axial force of the bolt increases again, so the bolt will not loosen.

Advantages and disadvantages of double-stack self-locking washer

The double lock washer can be used in petrochemical, railway, electric power, rail, locomotive, ship, wind power, bridge, lifting equipment and other fields.

Advantages: The locking function is not affected by lubrication, and has the advantages of durability, reusability, stability and reliability.

Disadvantages: Not suitable for light metal, precision assembly and other conditions of connection, which will have some impact on surface wear and crush.